November 2025

Addiguru to Exhibit at Formnext 2025

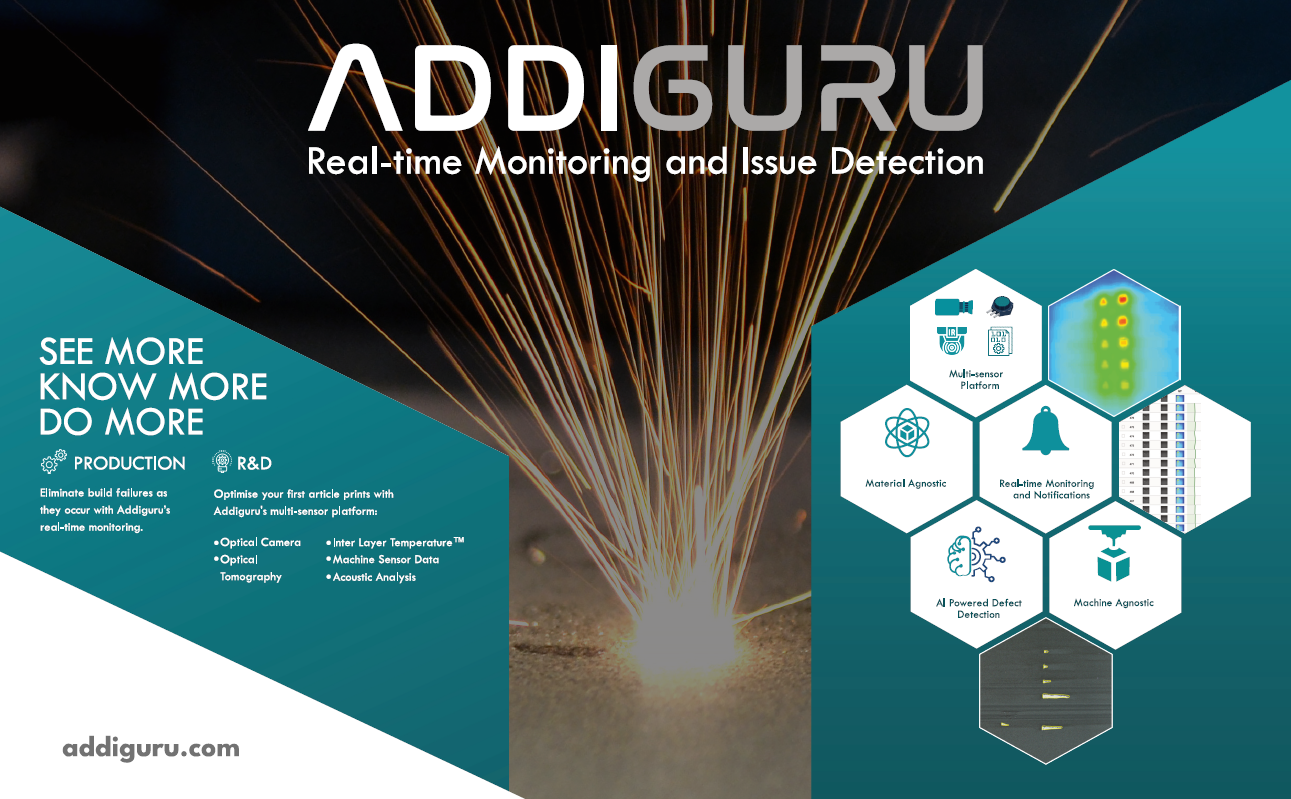

If you’re heading to Formnext 2025, we’d love to show you what’s new at Addiguru. Since last year’s show, many teams told us the same thing: we’re spending too much time and money on CT scans just to confirm we’re printing scrap. So we focused on prevention—fusing optical, thermal and machine data to detect issues before they become visible.

With our latest release, swelling and deformation are flagged much earlier—often 50–100 layers before they’re visible—helping teams save hours of machine time and expensive material.

Drop by and see how multi-sensor, automated analysis helps shift from reactive inspection to proactive control.

What you’ll see at our stand

- Live demos of real-time monitoring and issue detection.

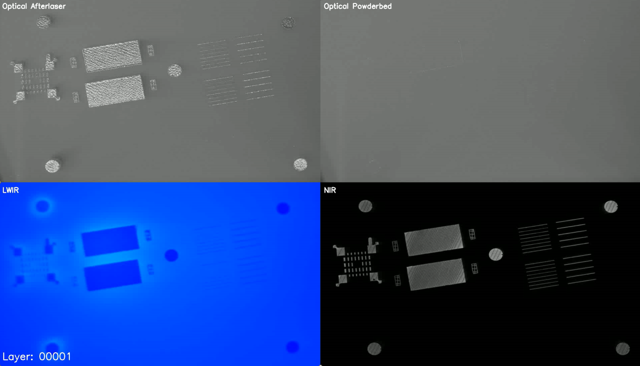

- Optical & thermal data fused with machine signals for a complete view.

- Integrations with Renishaw Central, EOSCONNECT and more.

- New capabilities in automated defect detection and multi-modal data fusion.

Hall 11.0 | Stand B57 | 18–21 November | Frankfurt

Book a Meeting at FormnextLatest News

New: Next-Generation Multi-Modal In-Situ Monitoring

Debuting at Formnext 2025 (Hall 11.0, Stand B57), our latest release helps engineers act faster, reduce waste, and gain confidence in every build.

Save time and money on failed builds

- Instant recoat issue detection.

- Near-infrared detection of hot spots and lack of fusion.

- Gas-flow change detection (NIR).

- Inter-layer temperature to detect heat accumulation.

Save your builds during production

- Inter-Layer Temperature for heat accumulation.

- Thermal modalities predict distortion 50–100 layers early.

Speed up parameter development

- Thermal data informs heat accumulation and thermal profiles.

“Most systems say what went wrong. Addiguru helps you see why — and fix it before the part fails.” — Shuchi (SK) Khurana, CEO

Co-Winner: ASTRO America In-Situ Monitoring Challenge

Thrilled to share that Addiguru has been named the co-winner of ASTRO America’s inaugural Actionable In-Situ Awareness Challenge! 🎉 Out of 10 companies that applied, five were selected as finalists to demonstrate their solutions live. Competing alongside some of the most innovative teams in the field, Addiguru showcased our multi-sensor, AI-driven in-situ monitoring platform—proving how real-time defect detection and actionable insights can accelerate adoption of additive manufacturing across aerospace, defense, and commercial industries.

This recognition is a huge milestone for Addiguru and a testament to the hard work of our team, partners, and supporters.

TCT Podcast — Addiguru on stopping scrap early

What would change if you could spot defects in minutes instead of days—and know the likely cause?

- Stop scrap early with multi-sensor monitoring

- Turn data into actions and clear reports

- Qualify faster with evidence

🎧 Listen: https://lnkd.in/e98Qxsjt

Addiguru joins the Manufacturing Technology Centre (MTC)

We’ve joined the MTC as a Tier 3 member to support collaborative research and help manufacturers adopt reliable, production-ready AM monitoring.

“Joining MTC lets us work closely with leading teams and share AI-driven monitoring that improves process control and early defect detection.” — Shuchi “SK” Khurana, CEO

“Addiguru’s automated defect detection is a significant step forward for AM. We’re keen to explore its capabilities within the MTC network.” — Dr Ben Dutton, Technical Specialist, MTC

3D Adept Magazine Feature

Post-processing | In-situ monitoring vs. post-process inspection: complementary tools or competing technologies?

Shuchi “SK” Khurana (Addiguru) and Dr. David Menzies (Additive Assurance) share where monitoring and inspection meet—and when each adds the most value.

👉 Read: https://lnkd.in/dzV7Qip6

Reserve a slot with our team

addiguru.com