Features

Addiguru has built its software features based on user feedback, customer needs, and individual custom requests.

- Easy to use interface

- Build reports

- Different types of Anomalies

- AI Detection Sensitivity Control

- Anomaly to Defect

And many more

- Analyze Real-time as well as previous data

- 3D View

- Color coding by anomaly severity high/medium/low

- Intelligent Imaging

- Interlayer Temperature

- Acoustics

- Time lapse of the whole build

- Machine Build data analysis

- Perspective correction

- Multiple Modalities

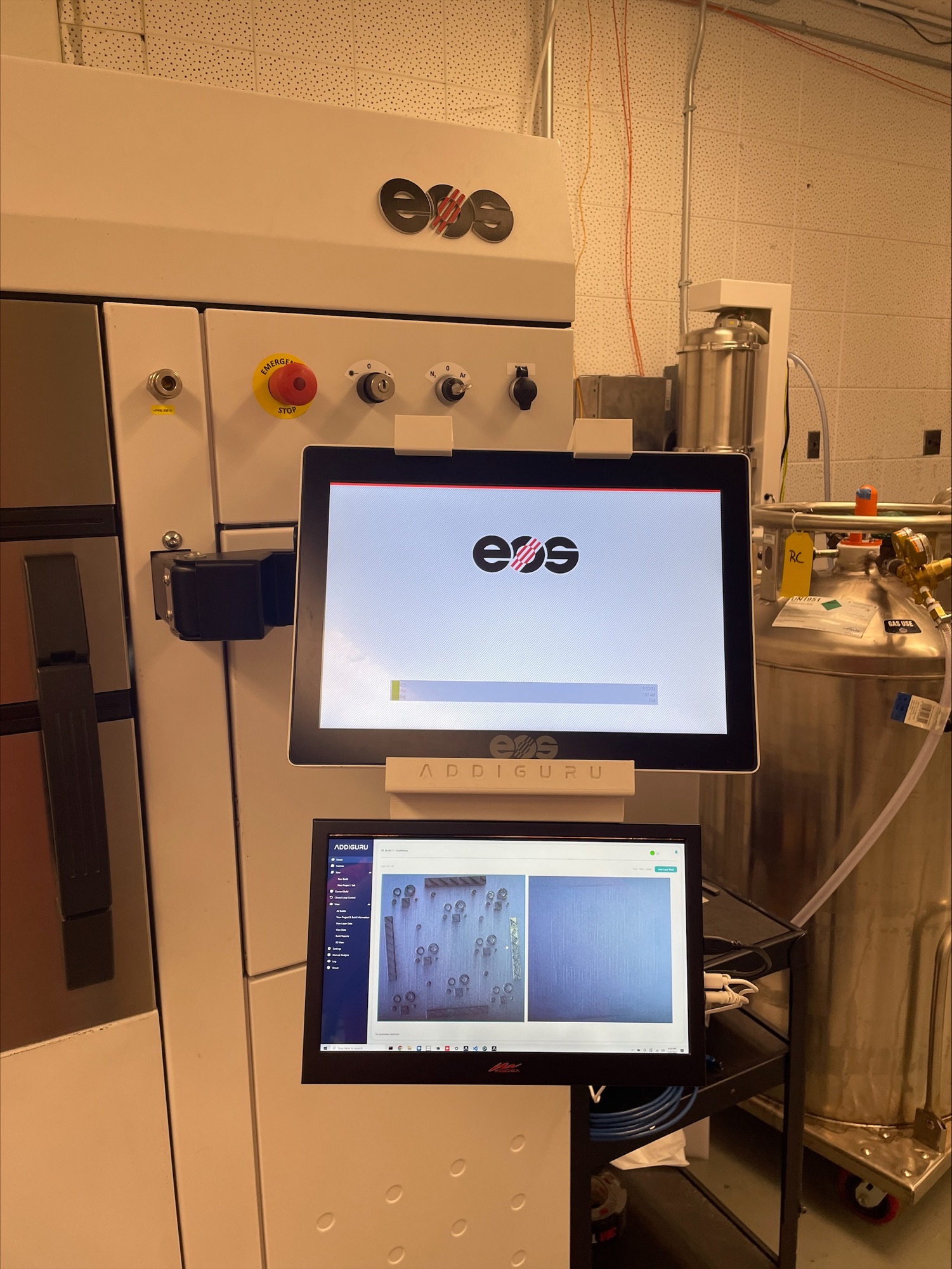

- Touch screen at machine

- Auto start / stop

- Close loop control

- Remote live view camera

- Record snippets of video from process

- Local Install – Secure use (Use your own network and computer)

Installs

Installation to your AM machine in less than 1 hour. The Addiguru tool was developed for easy installation to your machine and has been applied to 25+ different installs: US, Europe, and APAC. These installs represent 10+ different machine OEMs and 13+ different machine models.

| Machine OEM | Machine Types | # Installs |

|---|---|---|

EOS

|

M290, M400, M400-4, M300 (Beta) | 11 |

| GE Additive (Concept Laser) | M2, X-Line 2000 | 2 |

| 3D Systems | DMP350 | 2 |

| Renishaw | AM500 | 1 (coming soon) |

| Xact Metal | XM200G | 1+ |

| Open Additive | Panda | 2 |

| Addup | F350 | 1 (coming soon) |

| Farsoon | FS301-M | 1 |

| SLM | 280 | 2 |

| Aconity3D | AconityONE | 1 (coming soon) |

| Others | Confidential, Cannot List | 3 |