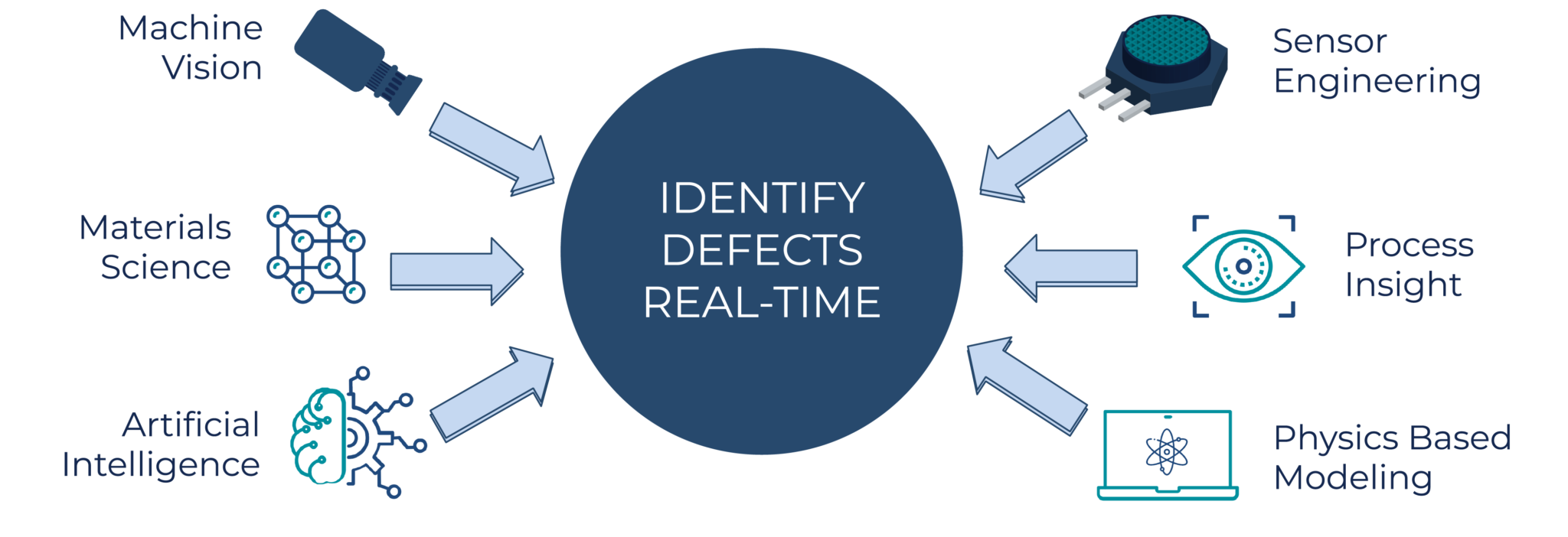

In situ Process Monitoring

and Issue Detection

The Software

Addiguru provides in-situ monitoring and issue detection technology for the Additive Manufacturing (AM) processes. Addiguru software can process data from different sensors - optical, thermal and machine sensors. The data is then analyzed automatically by artificial intelligence and machine learning algorithms to tell a user about probability of defect in a build.

Independent of machine and materials, Addiguru's intelligent technology can be easily incorporated into existing and newly developed AM equipment. Part anomalies formed during the build process are difficult and costly for post build detection and repair. Addiguru's monitoring technology detects anomalies during the build process and provides notifications to the users within seconds of layer formation.

Benefits

- Confidently make informed decisions to reduce V&V time

- Improved quality assurance

- Cost reduction via increased efficiency & failed build savings

- Automatically convert data into actionable information

- On-demand generation of build reports and data logs

Why Addiguru?

- Industry leading AI algorithms for defect detection

- Superior customer service & support

- US Defense (DoD) and global commercial users and partners

Issue Detection

Addiguru’s in-process monitoring solutions collect appropriate amount of data with decision-making information. The software leverages the layer by layer and other information to provide analysis. With team’s unique knowledge of materials science, computer vision, and artificial intelligence Addiguru has developed a novel technology to process multiple sensor data and provide in-situ quality monitoring results with high accuracy in the industry.

Saving Time and Money For Industry Partners

Featured In...