Defects in 3D printing can be stochastic, but that shouldn’t keep you from running long prints. At least, not with Addiguru real-time monitoring software!

We all have had times when your print goes amiss and all you see is a spaghetti monster instead of a clean near net shaped part. Defects such as spaghetti most commonly are seen in situations where there is lack of support for overhangs, loss of adhesion due to changes in build chamber, or toppling of part due to lost adhesion with the print bed. Whatever the reasons be, spaghetti invariably results in a failed part, waste of material and more importantly lost time.

Addiguru’s real-time monitoring solution for Fused Deposition Modeling (FDM) processes uses inexpensive optical cameras to monitor for defect such as spaghetti, delamination, material obstruction, etc. and notifies user of any anomalies instantly. The software runs on Windows as well as Raspberry Pi and is compatible with Raspberry Camera’s as well as standard webcams.

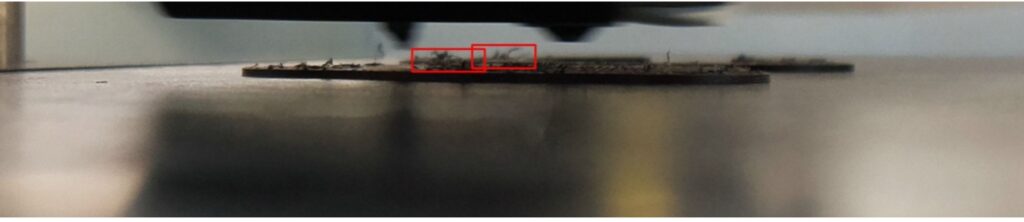

As seen in the example below, the software detects spaghetti very early in the stage and sends a notification to the user.

Addiguru’s innovative monitoring system is powered by artificial intelligence and computer vision algorithms offering high accuracy in real-time. The software has been rigorously tested to monitor long prints that can span over days at a time so that you, the user, can invest your valuable time to things that matter the most.